Time for a shop tour! Every now and then, I’ll be taking a snapshot in time of the workshop. The purpose will be to see how it changes over time, and also to give you, the reader, a more detailed look, as well as my goals for the future of the workshop and this blog.

The story of the current state of the workshop will be mostly told in pictures

![]() , and I’ll finish with my future plans for the workshop.

, and I’ll finish with my future plans for the workshop.

Further, this is the first post that is finally caught up to the present day!

And now all future posts can be close to real-time ![]() I’ll be posting

as things happen, and also having some sort of social media presence soon that I

haven’t finalized yet, but will be linked in the blog.

I’ll be posting

as things happen, and also having some sort of social media presence soon that I

haven’t finalized yet, but will be linked in the blog.

Garage Tour

Garage Tour

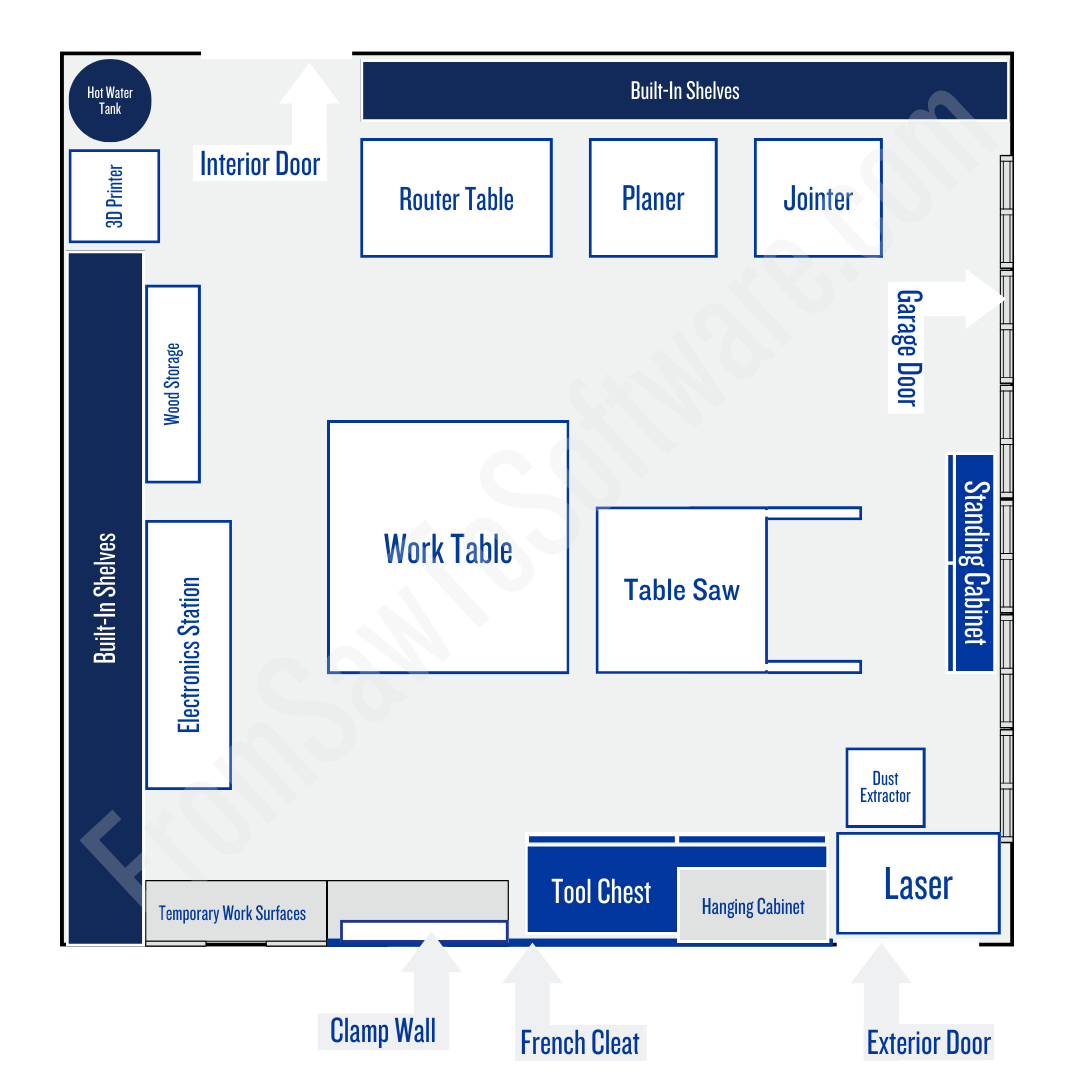

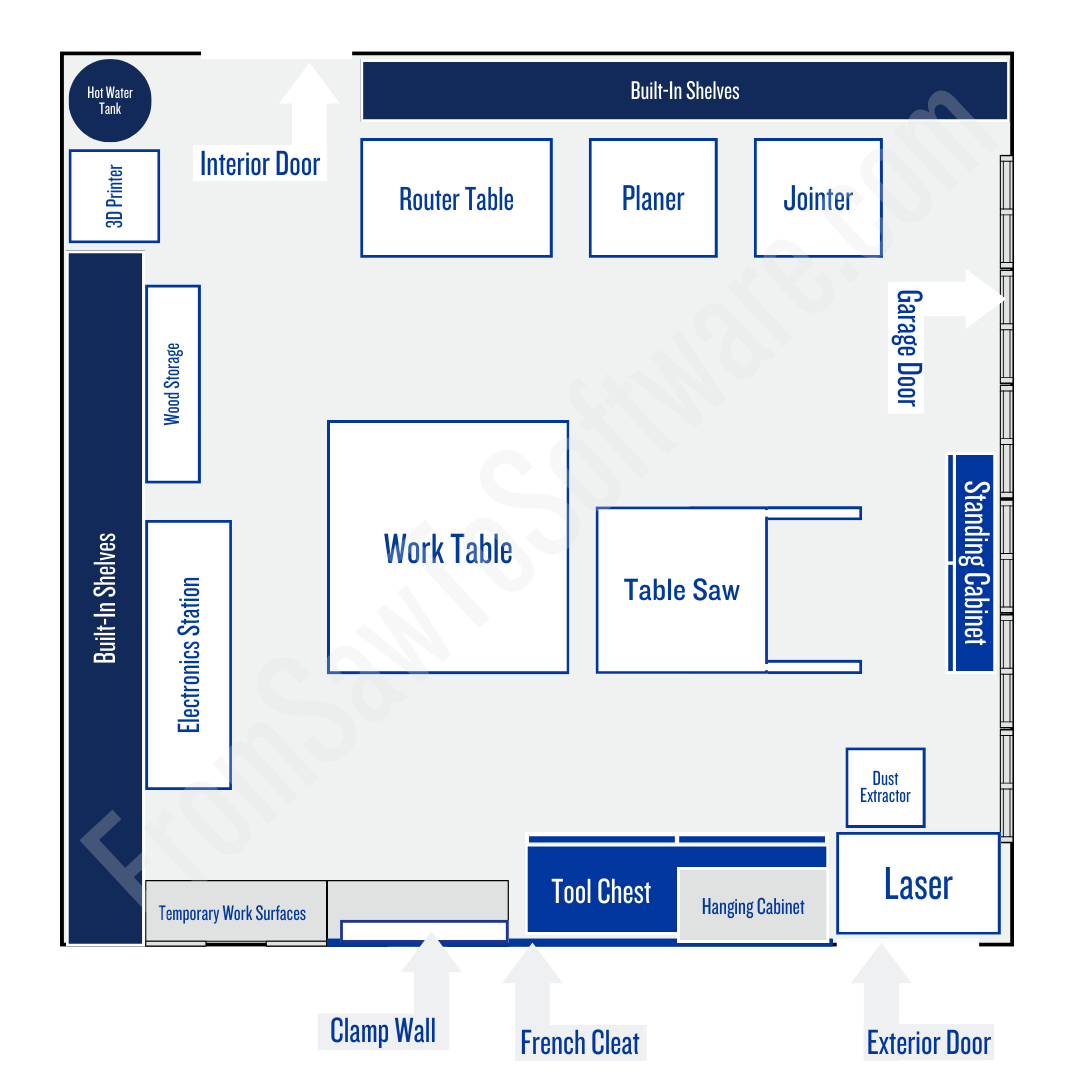

I’ve broken this into three parts: woodworking, electronics, and CNC machines. Software will be covered in another section since it’s not located in the garage.

|

|---|

| Garage workshop layout diagram, with woodworking taking up most of the room, electronics station on the left, and CNC machines in two of the corners |

Woodworking

Woodworking

|

|---|

| Woodworking portion of the workshop |

|

|---|

| Table saw and outfeed / work table, with clamp wall and dust extractor in the background |

|

|---|

| Outfeed / work table, waxed for protection and maximum slickness to lower the chances of wood snagging on it |

|

|---|

| Clamp wall, with more clamps added since it was built |

|

|---|

| Hanging cabinet contents, with quick access to commonly used large tools on bottom; glue, finishing materials, and chemicals on middle; bits, setup blocks, and accessories on top |

|

|---|

| Tool chest contents, with commonly used hand tools on top, and many tools, jigs, and fasteners in the remaining drawers; one of the drawers for my wife’s |

|

|---|

| Standing cabinet contents, with air compressor and empty cases on bottom; uncommonly used large tools on second shelf; charging station (incomplete), Forstner bits, dado blades, and table saw accessories on third shelf; push blocks, extra sandpaper, cups for chemicals, and random materials on top; hex keys on the doors |

|

|---|

| From left to right: router table, planer, and jointer |

|

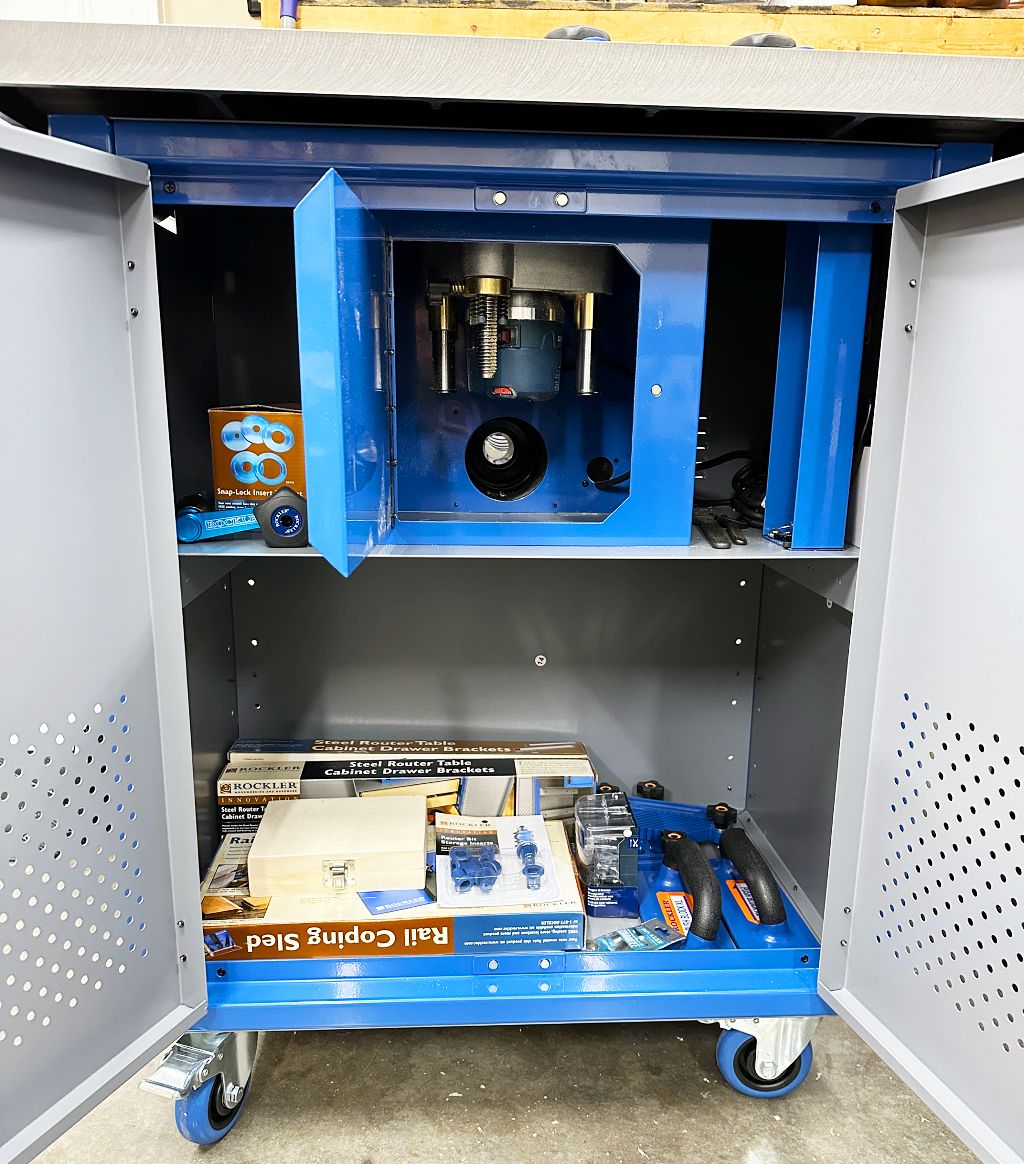

|---|

| Router table cabinet, with push blocks, bits, and uninstalled drawer slides on bottom; table rings, lift crank, router wrenches, and router box on top |

|

|---|

| Even though I prefer push blocks, every machine that could require a push stick has a magnetically attached push stick on its side, just in case I need one quickly while using it |

Electronics Station

Electronics Station

|

|---|

| Electronics station, VERY incomplete |

There is definitely a lot I want to do here! I have a lot of electronics equipment in the house that I want to bring out here, but I’ve resisted due to the wood dust. I’ll discuss this more in the Future Plans section.

CNC Machines

CNC Machines

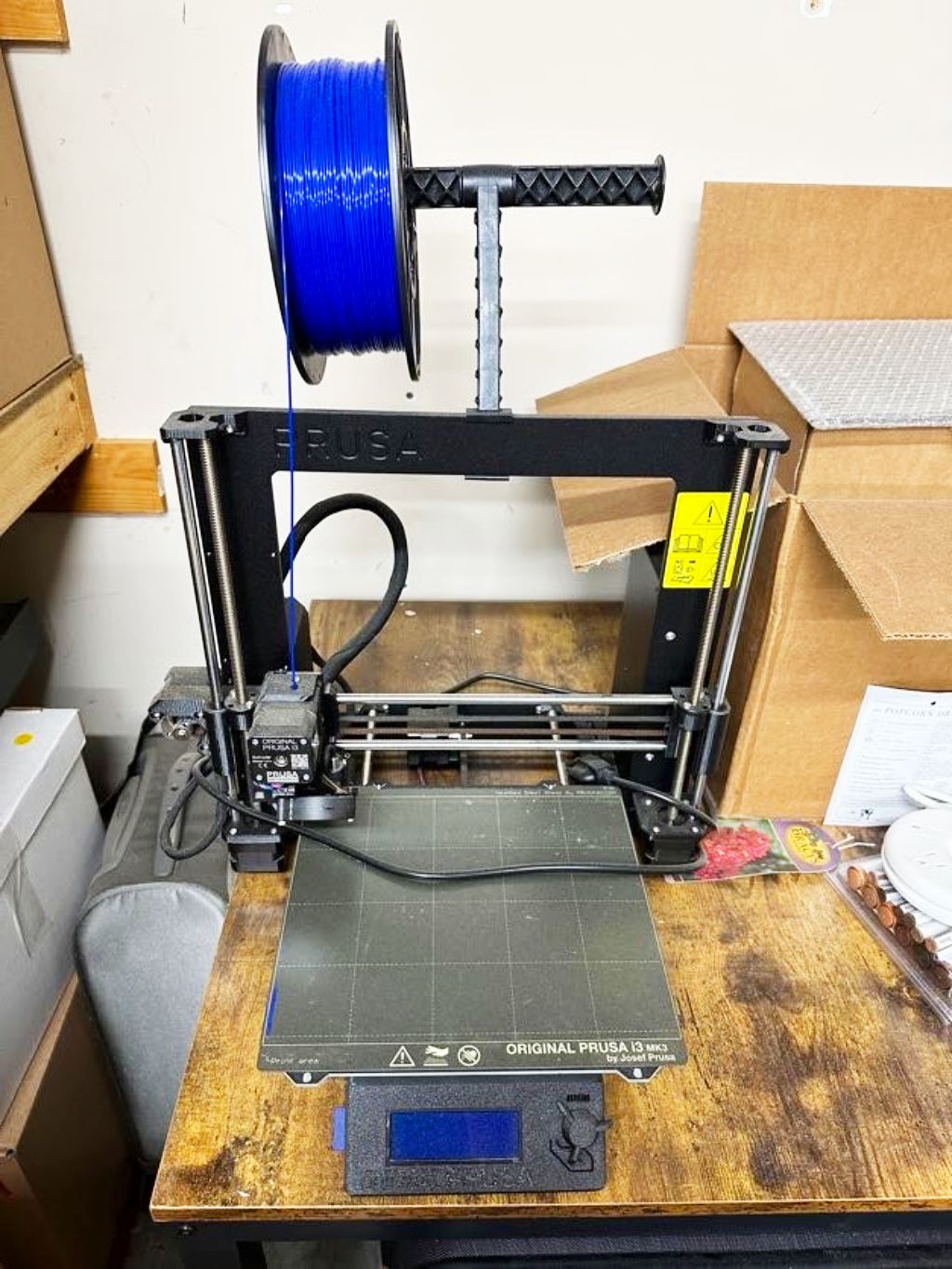

|

|---|

| 3D printer, currently inoperable |

Neither the 3D printer nor the laser (not pictured) are currently in use, but I’d like to change that and integrate them into my workflow! I’ll discuss this more in the Future Plans section.

Software

Software

I have two computers: one for my job, and one for my personal computer. I solely

use my personal computer for my projects, since it has the better screen and

specs. I do wish that I had a motorized standing desk, but the shape of the room

prevents it. Otherwise, I’ve very happy with my current setup ![]() Though, I

do need to work on cable management

Though, I

do need to work on cable management ![]()

|

|---|

| Personal computer and desk setup. I’m writing this article in this picture! |

|

|---|

| Personal computer closeup, with the cable management inside the case much better than on the outside |

I primarily use JetBrains software for full stack work (mostly PyCharm and WebStorm), and the standard Arduino IDE for Arduino work. I’ve used various software for electronics work and also Fusion360 for CAD/CAM work. However, I’m looking for other solutions for this type of work—preferably open source and on-premises solutions—and I’m sure I’ll cover more about this in a later article.

Future Plans

Future Plans

I’ve broken this into short term and long term goals for my vision of the workshop. Short term goals are things I want to accomplish this year, and long term goals are things I want to eventually accomplish at some point in the future, but there is no hard time limit.

I’ll also list everything in loose order of importance, but this is not a strict

order. I’ll be working on things as we feel like it. And it is definitely a

we thing. My wife ![]() is just as much a part of this as I am, and I

wouldn’t have it any other way

is just as much a part of this as I am, and I

wouldn’t have it any other way ![]()

Before we start, here is a reminder of the current layout of the workshop:

|

|---|

| Garage workshop layout diagram, with woodworking taking up most of the room, electronics station on the left, and CNC machines in two of the corners |

Short Term

Short Term

For 2024, I want to accomplish as much of the following as possible:

![]() Better Electronics Workstation—This area is so neglected, and I

have many ideas for projects which will take advantage of this area. I have

equipment in the house, like my oscilloscope, which I have resisted bringing out

here due to the wood dust. And the other equipment, such as my soldering

station, doesn’t have a true “place”. I’d like to address better dust resistance

for the area and also have a better layout for the equipment.

Better Electronics Workstation—This area is so neglected, and I

have many ideas for projects which will take advantage of this area. I have

equipment in the house, like my oscilloscope, which I have resisted bringing out

here due to the wood dust. And the other equipment, such as my soldering

station, doesn’t have a true “place”. I’d like to address better dust resistance

for the area and also have a better layout for the equipment.

![]() Shop Storage—I’m already having some issues with some of my

storage areas: some are too densely packed and hard to use, while others waste a

lot of space and could be better utilized. This problem will quickly get out of

hand as I do more diverse work, such as more electronics, etc. and I’d like to

get ahead of this now.

Shop Storage—I’m already having some issues with some of my

storage areas: some are too densely packed and hard to use, while others waste a

lot of space and could be better utilized. This problem will quickly get out of

hand as I do more diverse work, such as more electronics, etc. and I’d like to

get ahead of this now.

![]() Remove Built-Ins—These built-ins were here when we bought the

house. They’re okay, but not well laid out. We’ll keep the one at the top of the

diagram, but the other one on the left wall will be removed. Easier said than

done, since there is a LOT of stuff still on the shelves from when we moved.

Remove Built-Ins—These built-ins were here when we bought the

house. They’re okay, but not well laid out. We’ll keep the one at the top of the

diagram, but the other one on the left wall will be removed. Easier said than

done, since there is a LOT of stuff still on the shelves from when we moved.

![]() Mini Split—Otherwise known as a ductless air conditioner, this

will be a massive improvement over my oil heater and dehumidifier that I just

roll along the ground right now. If I want to store nice wood in the workshop, I

need to control the temperature and humidity. I’ll put this on the wall where

the built-in will be removed.

Mini Split—Otherwise known as a ductless air conditioner, this

will be a massive improvement over my oil heater and dehumidifier that I just

roll along the ground right now. If I want to store nice wood in the workshop, I

need to control the temperature and humidity. I’ll put this on the wall where

the built-in will be removed.

![]() Material Storage—For now, I’ve just been leaning wood on the side

of the garage built-ins, but I’ve also not had nice wood until now. Ideally, I’d

store all my wood up high (where the built-in will be removed) so that there is

no contact with the porous garage floor getting the wood wet, flat so that it

doesn’t warp, stacked in a way that I can see what I have and get to it easily,

and I want it out of my way since floor space is at a premium.

Material Storage—For now, I’ve just been leaning wood on the side

of the garage built-ins, but I’ve also not had nice wood until now. Ideally, I’d

store all my wood up high (where the built-in will be removed) so that there is

no contact with the porous garage floor getting the wood wet, flat so that it

doesn’t warp, stacked in a way that I can see what I have and get to it easily,

and I want it out of my way since floor space is at a premium.

![]() 3D Printer—This was used a grand total of two times before it

collected so much dust over the years that I just haven’t bothered to use it.

I’ll want to clean it up before turning it on from not just wood dust but also

gypsum dust and more. Turning it on now will probably destroy it.

3D Printer—This was used a grand total of two times before it

collected so much dust over the years that I just haven’t bothered to use it.

I’ll want to clean it up before turning it on from not just wood dust but also

gypsum dust and more. Turning it on now will probably destroy it.

![]() Laser—Years ago, I had a business with my wife where we made custom

laser engraved items. The business is gone, but I still have the laser. I’ll

want to evaluate it to see if it still works, and if so, how to integrate it

into my workflow to be a value-add to my work. The laser is optimized to engrave

and cut wood and plastic, but can mark on metal with a molybdenum-based marking

solution.

Laser—Years ago, I had a business with my wife where we made custom

laser engraved items. The business is gone, but I still have the laser. I’ll

want to evaluate it to see if it still works, and if so, how to integrate it

into my workflow to be a value-add to my work. The laser is optimized to engrave

and cut wood and plastic, but can mark on metal with a molybdenum-based marking

solution.

![]() Band Saw—Something that I noticed when I went to the lumberyard

for the console bookshelf project (article

coming soon) is how important it will be to be able to resaw my own lumber to

make thinner pieces out of thicker pieces. I want to stop relying so much on my

planer which will just waste wood as it shreds through this nice thick wood to

make the thicknesses I want. And I’ll put it—you guessed it—where the

built-in will be removed.

Band Saw—Something that I noticed when I went to the lumberyard

for the console bookshelf project (article

coming soon) is how important it will be to be able to resaw my own lumber to

make thinner pieces out of thicker pieces. I want to stop relying so much on my

planer which will just waste wood as it shreds through this nice thick wood to

make the thicknesses I want. And I’ll put it—you guessed it—where the

built-in will be removed.

![]() Workbench—I need a better clamping solution and storage

for some of the hand tools I use. I am very much a hybrid woodworker, meaning I

use hand and electric tools, and I want to have a workbench that can accommodate

both. This will replace at least one of my temporary work surfaces.

Workbench—I need a better clamping solution and storage

for some of the hand tools I use. I am very much a hybrid woodworker, meaning I

use hand and electric tools, and I want to have a workbench that can accommodate

both. This will replace at least one of my temporary work surfaces.

![]() Miter Station—While I don’t have a miter saw, I do have my mobile

work table and table saw which I can use in a similar manner. But it would be

much more convenient when cutting long stock to have a miter station. I will put

this on the wall where the built-in will be removed.

Miter Station—While I don’t have a miter saw, I do have my mobile

work table and table saw which I can use in a similar manner. But it would be

much more convenient when cutting long stock to have a miter station. I will put

this on the wall where the built-in will be removed.

![]() Drill Press—I have a precision drill guide (that I haven’t used

yet), which I can use to drill holes in wood in a very controlled and precise

manner, but it’s still not the same as having a full drill press. Hmm, but where

should I put this?… I know! On the wall where the built-in will be removed

Drill Press—I have a precision drill guide (that I haven’t used

yet), which I can use to drill holes in wood in a very controlled and precise

manner, but it’s still not the same as having a full drill press. Hmm, but where

should I put this?… I know! On the wall where the built-in will be removed

![]()

Long Term

Long Term

I have no real time limit in mind for these, but I do know that I want to accomplish them eventually:

![]() Small Wood Lathe—Lathe work isn’t something I’m particularly

interested in doing manually, but I do want to make rings, knobs, chess pieces,

and other small parts.

Small Wood Lathe—Lathe work isn’t something I’m particularly

interested in doing manually, but I do want to make rings, knobs, chess pieces,

and other small parts.

![]() Metalworking—Ironically, my engineering degree focused on

giving me the expertise to design and analyze metal and plastic structures; and

yet, I have a workshop which can do almost no metalworking! I’d like to fix that

and get either a manual mill like a Bridgeport or a small enclosed CNC

mill/lathe like a Tormach. I’d also like to get a very simple welder for when

the occasional need arises.

Metalworking—Ironically, my engineering degree focused on

giving me the expertise to design and analyze metal and plastic structures; and

yet, I have a workshop which can do almost no metalworking! I’d like to fix that

and get either a manual mill like a Bridgeport or a small enclosed CNC

mill/lathe like a Tormach. I’d also like to get a very simple welder for when

the occasional need arises.

![]() More Space—I’ll eventually outgrow the garage workshop, but I

still want to be close to home. It’s likely we’ll move in the next 5-10 years

anyway, so I hope to have more land and build a large, detached workshop where I

can have different large sections/rooms for different things (e.g. paint,

electronics, finishing, etc.). I want it detached just in case I ever

accidentally start a fire

More Space—I’ll eventually outgrow the garage workshop, but I

still want to be close to home. It’s likely we’ll move in the next 5-10 years

anyway, so I hope to have more land and build a large, detached workshop where I

can have different large sections/rooms for different things (e.g. paint,

electronics, finishing, etc.). I want it detached just in case I ever

accidentally start a fire ![]() , my family will still be safe in

our home.

, my family will still be safe in

our home.

Sum-Up

Sum-Up

I didn’t realize how many goals I had for the workshop for this coming year

until I wrote this! And these goals are just for building out the

workshop—this isn’t even all the other projects I have in mind to complete

this year! I’m excited to get started on these, and I hope you’ll follow along

with me ![]() Please sign up for my newsletter below that will keep you up to

date with my latest articles and projects! The next project I’ll be starting is

the console bookshelf, and it’s my most

intimidating woodworking project yet, so keep an eye out for that!

Please sign up for my newsletter below that will keep you up to

date with my latest articles and projects! The next project I’ll be starting is

the console bookshelf, and it’s my most

intimidating woodworking project yet, so keep an eye out for that!

Until next time,

![]() Pixel

Pixel