(The following took place on the week of November 05, 2023)

Time to finish this mobile work table!

In part 1, I did the

planning, bought the materials, then cut and finished the wood construction of

the table—I would say that was the hard part! All that’s left is I need to add

the wheels, then sand, paint, polyurethane, and wax it. This table will be done

in no time at all ![]()

Starting Point

Starting Point

As a quick reminder, here is the table at the end of part 1. It’s just a table,

with no finish on it and no wheels. But it is technically a table that I could

use, if I needed to! That is, if I turned it right-side-up ![]()

|

|---|

| The wooden structure of the table is assembled, still upside-down |

Building

Building

While the table is still upside-down, this is a perfect time to add the wheels!

Wheels

Wheels

I bought some heavy-duty wheels from Amazon which should be able to take anything I throw at it. They also have this nice lever at the top that allows me to engage and disengage the wheels with my foot. This means I can have the table highly mobile when I want to move it around, or very stable when I want it to be stationary.

|

|---|

| The wheels, with the lever (red arrow) to engage and disengage them |

I drill some holes in the legs and screw the wheels in place. I place the wheels

on the inside of the legs so that they don’t stick out past the legs. This will

prevent the wheels from ever getting in the way, no matter where I put it! I am

always looking out for potential trip hazards in the workshop, and this

completely eliminates that possibility ![]()

|

|---|

| The wheels installed on the legs, and the lever up disengaging the wheels, my plastic table on top for a size comparison |

|

|---|

| The wheels installed on the legs, and the lever down engaging the wheels on the ground |

Mistake

Mistake

I have to guess at exactly where I should place the wheels relative to the bottom of the legs since there are no instructions in the box. I mistakenly think that I should place the wheels as close to the leg bottoms as possible to ensure that they’ll barely clear the ground when the lever is disengaged. This way, I’ll guarantee the wheels will be able to pick up the table high enough to miss any bumps on the ground while the table is rolling. Makes sense, right?

It works great when I engage the wheels: the table lifts off the ground nicely.

However, I didn’t realize that when I disengage the wheels, the wheels have

trouble getting fully out of the way, and the table wants to rest on these

wheels ![]()

|

|---|

| The lever disengaged (up position), but wheels not fully out of the way, and the table resting on them |

It’s not a big deal, since I can just wiggle the table a bit and the wheels will fully turn to the side and get out of the way. But it’s annoying, and the extra side loading on my table legs when I do this forceful wiggling isn’t great for the long-term structure of the table. I’ll make this better on any future mobile table I build, but hopefully you won’t make the same mistake I did!

Finishing

Finishing

This should be straight-forward! Sand, paint, polyurethane, wax, done!

Bada-bing, bada-boom ![]() And doing the finishing on a large

surface like a table is easier in some ways than finishing a smaller surface

like the hair bow box project.

And doing the finishing on a large

surface like a table is easier in some ways than finishing a smaller surface

like the hair bow box project.

Sanding

Sanding

I sand the entire table outside surfaces except for the legs with 120 grit

sandpaper, then 220 grit sandpaper. I’m not going to go wild with the sanding

since this is a workshop table, not a fine piece of furniture. I just want to

make sure there are no splinters or rough edges, and that my eventual waxing

will give me a surface that wood will glide on top of ![]()

|

|---|

| The table being sanded, taking advantage of the wheels to work outside |

|

|---|

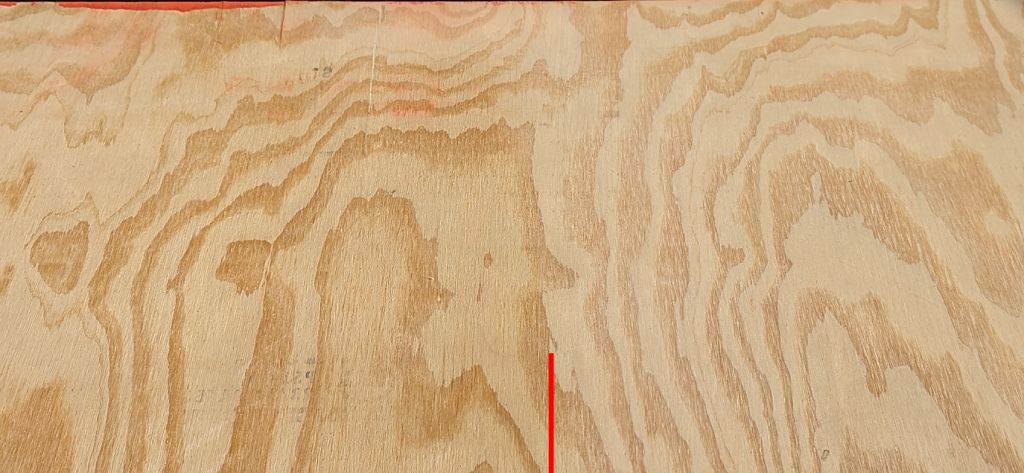

| The right half is sanded, with the left half not sanded yet, red line marking the boundary |

I attempt to sand off the orange/red paint on the border of the plywood, but

it’s not coming off easily. That confirms it: I’ll be using my blue paint, after

all! See, it’s not that there was paint on my table that I wanted to get off,

it’s that I wanted it to be blue ![]() #MyAesthetic

#MyAesthetic

Painting

Painting

My wife ![]() is the MUCH better artist of the two of us. And even though it’s

just painting the edge of a table, I will still find a way to mess it up if I do

it

is the MUCH better artist of the two of us. And even though it’s

just painting the edge of a table, I will still find a way to mess it up if I do

it ![]() So I ask her to do it for me, and she does a great job! We always

enjoy finding a way to get involved in what the other is doing, so this works

out nicely

So I ask her to do it for me, and she does a great job! We always

enjoy finding a way to get involved in what the other is doing, so this works

out nicely ![]()

|

|---|

| The table edge being painted by my amazing partner-of-forever |

|

|---|

| The table edge painted and dried |

Look at those crisp edges on the top without even taping there! ![]() We only had to tape the bottom of the edge.

We only had to tape the bottom of the edge.

Polyurethane

Polyurethane

The paint dried very quickly! So since she was already out here with me, I was

able to get some extra bonus help ![]() to apply the water-based polyurethane!

I wanted a very durable surface, and one that would take my wax finish very

well. We applied 3 coats, lightly wet sanding in between.

to apply the water-based polyurethane!

I wanted a very durable surface, and one that would take my wax finish very

well. We applied 3 coats, lightly wet sanding in between.

AND!! I learned from the hair bow box project, and I

remember to spray some water on my wood and sand it before the first coat

![]() This helps the wood fibers stand up to be sanded off and make the

surface even smoother.

This helps the wood fibers stand up to be sanded off and make the

surface even smoother.

|

|---|

| The table being prepped for polyurethane application outside, with a brush for each of us on the table |

|

|---|

| The table with 3 coats of polyurethane applied, dried, and ready for waxing |

I now have a hard, durable surface, but not an especially slick surface. I’ve got just the thing for that…

Waxing

Waxing

I use paste wax on all the machines in the workshop… which is only the table saw right now. But I’ll be adding more machines in the future, and I’ll be waxing them all with this!

Paste wax in an amazing way to protect metal surfaces from rust, and to make

them slick so that wood glides across them easily. Plus, there is no silicone

in it, and this is very important since any silicone that gets on wood can react

horribly with any finish that is then applied to the wood—it practically ruins

the piece ![]()

Since the table is so big, I only wax a quarter of the table at a time, taking

my time to ensure I cover every spot. I just use a blue shop paper towel to

apply it, wait 10-15 minutes, then buff it with another towel. The sheen of the

polyurethane is reduced a bit due to the wax, but it is WAY slicker now, and

that is what is important. I can place a piece of wood on the tabletop, and

barely push it, and it practically flies off the other side! ![]()

|

|---|

| The table fully waxed |

Now, time to put it in its final place in the workshop!

Final Reveal

Final Reveal

|

|---|

| The final outfeed and work table, next to the table saw where it will stay most of the time |

|

|---|

| The final outfeed and work table, at the perfect height for the table saw, as illustrated by the level simulating a piece of wood |

I’ve never built a table before! Which makes it even more surprising that I

didn’t do my typical amount of research before I started on this project—I

usually like to find what others have done and use that as a starting point. But

you know what? This was very freeing and enjoyable ![]() But only

because it all worked out in the end

But only

because it all worked out in the end ![]()

This was a very empowering project to build a large table from just some Lowe’s

wood and screws. And I have to say, I’m very proud of how it turned out!

Especially the consumable top that I can easily replace in the future by quickly

unscrewing all the pocket screws, putting a new piece of plywood on top, and

simply screwing it back in place through the same holes ![]() I’m sure others

have thought of this, too, but I haven’t seen it before and was excited to

figure out how to do it on my own!

I’m sure others

have thought of this, too, but I haven’t seen it before and was excited to

figure out how to do it on my own!

I’ll certainly be getting a lot of use out of this, and it feels good to be able

to build something to solve a problem that directly affected me, and will also

help keep my fingers safe from the table saw blade ![]()

![]() Pixel

Pixel