(The following took place on the week of September 12, 2023)

Continuing from my last article here, I’ll discuss the design I had settled on, then we’ll get to building!

Design

Design

|

|---|

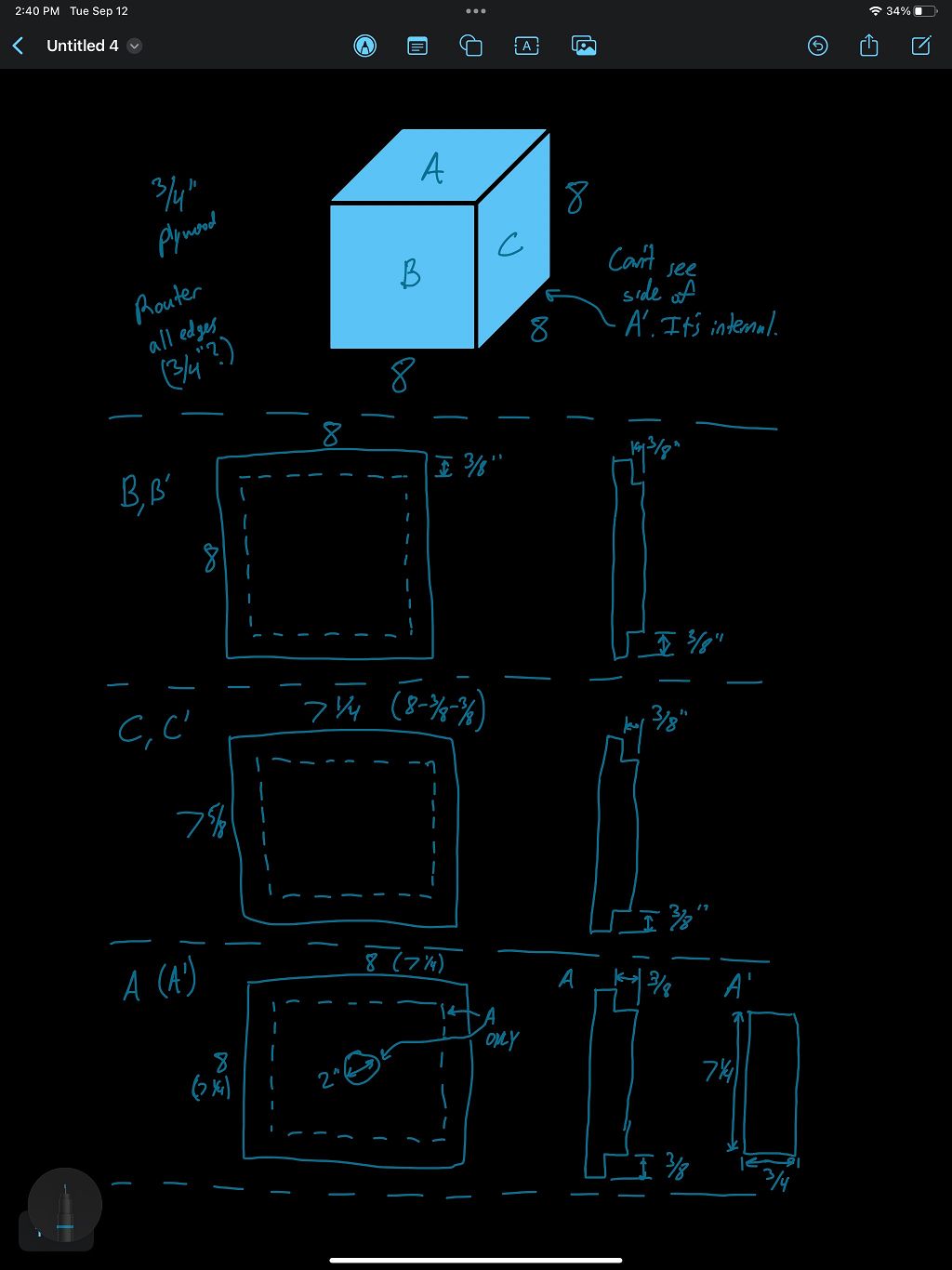

| Initial design for the hair bow box |

The first thing I want to call out is the hole in the lid, which will have its edges sloped into the opening of the box for two reasons:

- It will act as a comfortable two-finger handle to lift off the lid.

- It will allow hair bows to be placed into the box without needing to lift the lid.

Also, all the edges will have a 3/4” (19mm) radius. This will not only look nice

with the 3/4” plywood, but will also make the box more comfortable to handle and

not risk scratching my wife’s ![]() nightstand it will be going on.

nightstand it will be going on.

The height of the box will be twice as much as currently needed to account for:

- She’ll be able to fit more hair bows in the future.

- She’ll have room to dig into the pile with her hand when picking out a hair bow and none spill out.

While not pictured, I’ll also want to apply some sort of finish to the box, and

also some sort of fabric to the inside. The fabric will prevent the hair bows

from getting scratched by the plywood and make it look like a more finished

product such as a jewelry box. I’ll figure that out as I go so that I can go

ahead and get started ![]()

Building

Building

The time of putting pen to iPad is over. Time to do something!

I’ll begin by cutting out all the pieces to size, then I’ll cut the grooves in the ends of the pieces so that they’ll all fit together.

Cutting

Cutting

|

|---|

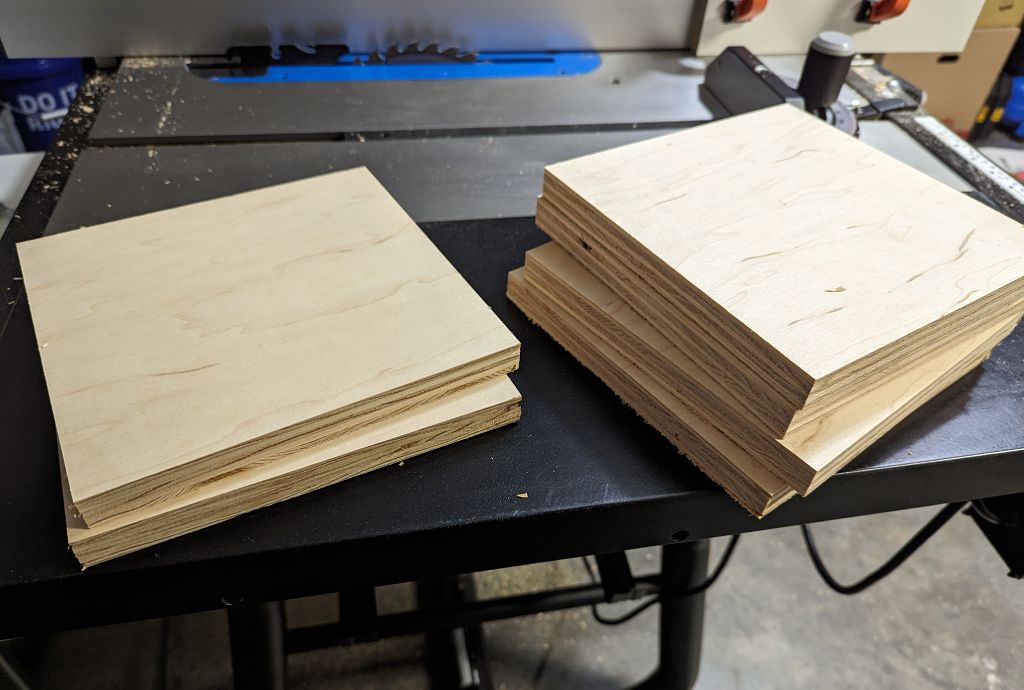

| My first cuts in around 15 years! |

First of all, let me say that it is thrilling to finally be putting metal to

wood again! ![]() It is also a bit nerve-wracking as I am again

getting used to the feeling of air hitting my hand from a spinning blade that

can rapidly disassemble my hand

It is also a bit nerve-wracking as I am again

getting used to the feeling of air hitting my hand from a spinning blade that

can rapidly disassemble my hand ![]() But it is a very empowering thing

to be able to make something with your own hands, and I’m glad to be back at it.

But it is a very empowering thing

to be able to make something with your own hands, and I’m glad to be back at it.

Anyway, as I’m cutting all 6 sides of the box, I notice this really cool accent

of brown through the surface of the plywood, near the bottom of the picture

above. I realize this would make a nice flourish to the final product if I can

keep that accent on the outside of the box and make it look continuous around

two of the sides. It would also serve as a nice additional challenge for me to

figure out how to do that. Let’s see how that goes… possible foreshadowing??

I hope not. ![]()

Now, due to how some of the sides will have to fit into each other, each piece

is not exactly the same size. This means it is very important for me to keep

track of which piece is which. And I should definitely NOT mess that up, because

I would then have to recut the piece, and I would have to do that for every

piece that was cut after that one. ![]()

Well… it started off good! My 8-inch (20cm) cuts are exact:

|

|---|

| Setup blocks for 8-inch (20cm) cuts |

|

|---|

| Exact 8-inch (20cm) pieces |

However, while I am celebrating the success of making the shorter cuts…I

discover that I did those cuts on the wrong pieces. And then when I try to fix

it, I make it too much shorter AND on the wrong piece!! ![]() Someone is more

out of practice than initially assumed

Someone is more

out of practice than initially assumed ![]()

It’s fine! I can adapt, and the box will be a little smaller than originally planned. The box was going to be twice as tall as it needed to be anyway, so I have the margin. I cut the other pieces to match—doing it right this time—and I am very pleased to see everything cut to the right size and in a pile on my table saw.

|

|---|

| Pieces cut to the “correct” size |

Groovy

Groovy

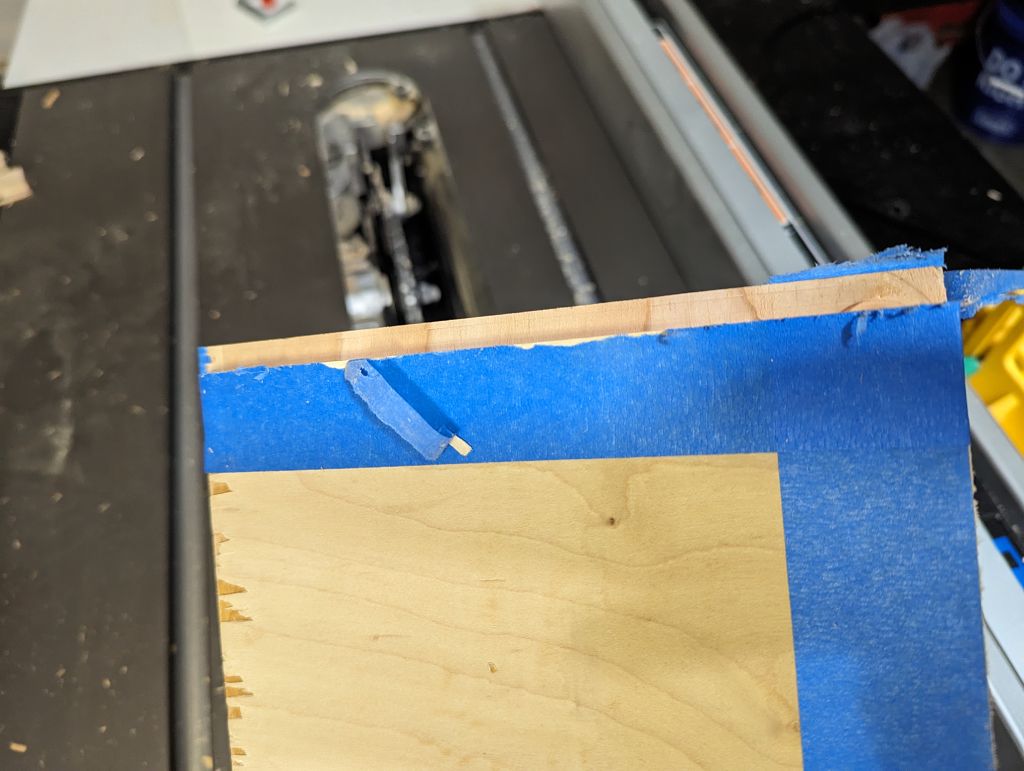

All the pieces need grooves on their ends, and these grooves are called “rabbets” (not rabbits), but not all pieces need the same rabbets. For this, I’m going to use what is called a “dado stack” on my table saw, which is a fancy way of saying I’m going to stack multiple blades on my table saw to make a wider cut. This will allow me to make the rabbets in one pass, instead of having to make multiple passes with a single thin blade. It will be roughly 3/8” (9.5mm) wide, and 3/8” deep. You can see the depth measured here:

|

|---|

| Depth measurement for rabbets with full dado stack installed |

However, as I’m making my first cut, this happens: ![]()

|

|---|

| Severe splintering on the side |

This is not good! Thankfully, I have noticed it after only the first piece, and this is on the inside of the box where I’m planning on putting some fabric anyway. I’ll apply blue tape to the rest before cutting, and that will prevent most of the splintering.

|

|---|

| Blue tape applied to prevent most splintering on this cut |

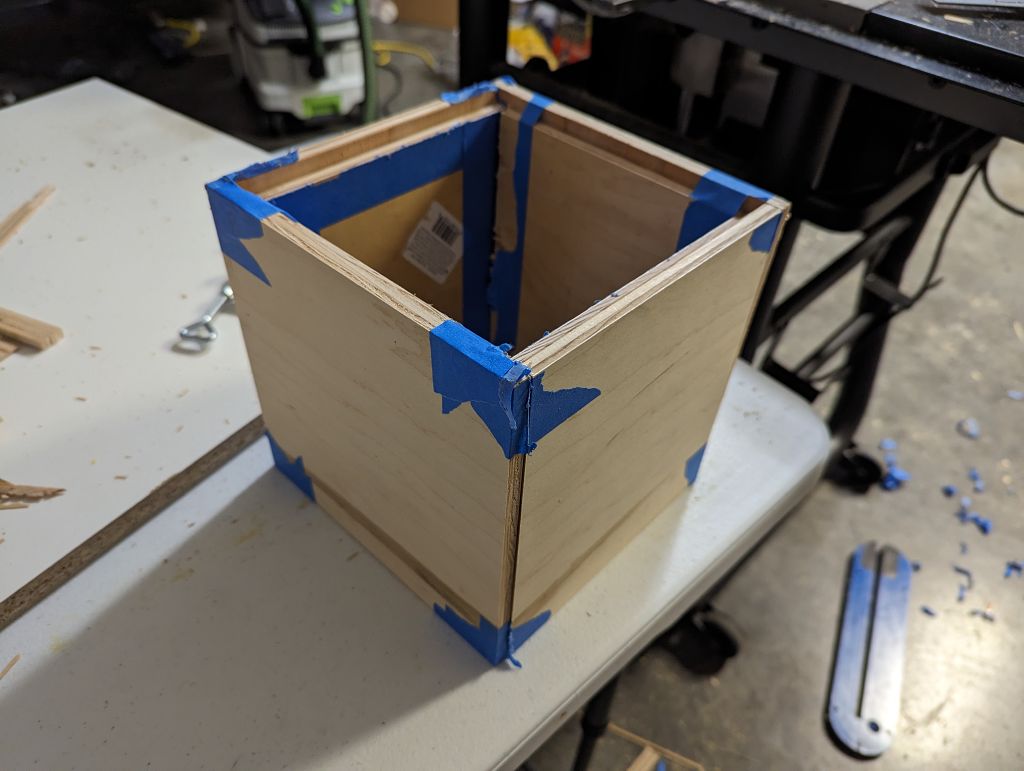

After cutting all the pieces and before removing the blue tape, I do a quick dry

fit to see if I need to make any adjustments to my rabbets. Not only do I see

that it all fits well together, but I am immediately reminded of the happiness I

get from seeing the progress of building something ![]() It’s

not much yet, but I can see the potential!

It’s

not much yet, but I can see the potential!

|

|---|

| Successful dry fit of the box, with brown accent lined up |

Quick Note on Safety

Quick Note on Safety

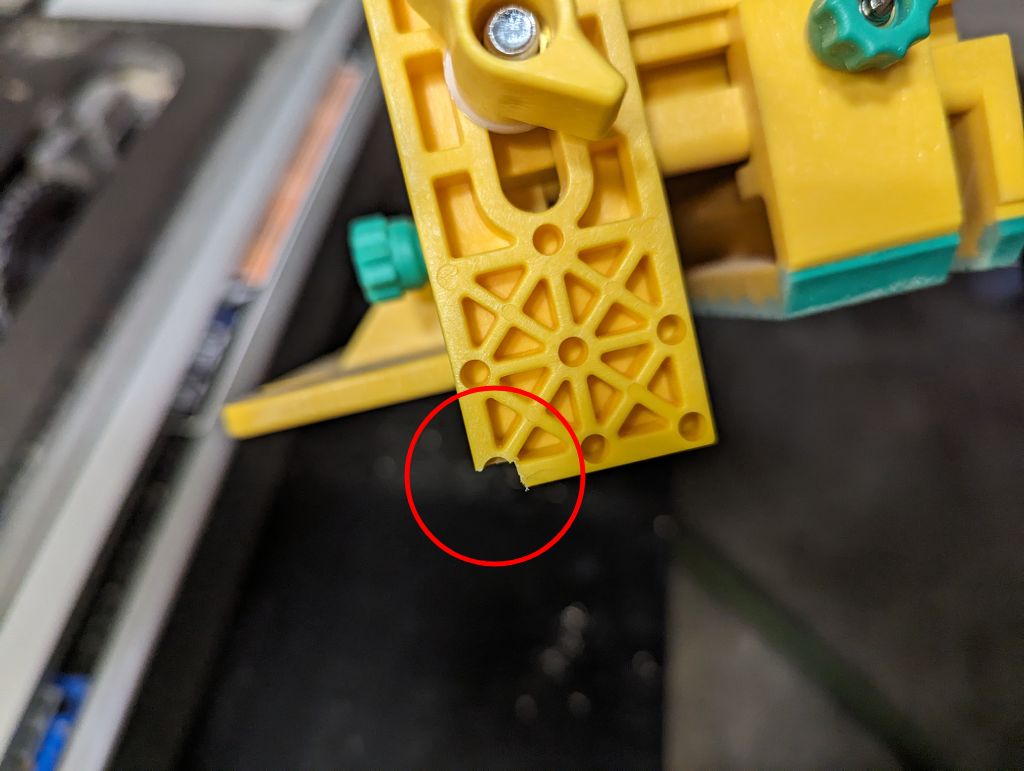

After I did my cutting, I noticed an interesting little notch on my push block:

|

|---|

| Unexpected notch on push block from cutting the rabbets |

Now, this part of my push block is meant to be sacrificial, which means I expect

to destroy it over time by cutting through it. However, what is scary about this

is that I did not mean to hit this with my blade here! In fact, I’m unsure how I

even got close enough to my blade for this to happen. That means if I were NOT

using my push block, my hand would have no longer been completely intact during

one of my cuts! ![]()

But, this is a good thing! You always want to keep your hand as far away from

your blade as possible, and this is proof of why you should always use a push

block or push stick. That means my safety process is doing its job ![]() And

this is a good example of how quick these machines can make you have a very bad

day if you’re not following good safety practices. Never get complacent or lazy

and not use your safety equipment! If you’re starting to get lax, it’s time to

take a break or come back to it tomorrow.

And

this is a good example of how quick these machines can make you have a very bad

day if you’re not following good safety practices. Never get complacent or lazy

and not use your safety equipment! If you’re starting to get lax, it’s time to

take a break or come back to it tomorrow.

And I will, of course, continue to get better about knowing where my hands are

in relation to the blade, since the best safety is to not have to rely on your

safety equipment to save you from yourself ![]()

Next Time!

Next Time!

I’ll continue this build in the next article, where I’ll be gluing together the box, using a router for the first time since high school, and figuring out the final fabric and finish on the box. See you then!

![]() Pixel

Pixel